| Tip | Not all racks use exactly the same type of mounting screws or mounting equipment. Make sure that you have sufficient screws or mounting gear for the types of racks you purchase. |

Wall-Mounted Brackets

For small installations and areas where economy of space is a key consideration, wall-mounted brackets may provide the best solution. Wall-mounted racks such as MilesTek's Swing Gate wall rack in Figure 1 have a frame that swings out 90 degrees to provide access to the rear panels and includes wire guides to help with cable management.

Racks such as the one in Figure 1 are ideal for small organizations that may only have a few dozen workstations or phone outlets but are still concerned about building an organized cabling infrastructure.

| Tip | Prior to installing wall-mounted racks with swinging doors, be sure to allow enough room to open the front panel. |

Skeletal Frames (19″ Racks)

Skeletal frames, often called 19″ racks or EIA racks, are probably the most common type of rack. These racks, like the one shown in Figure 2, are designed and built based on the EIA/ECA-310-E standard, issued in 2005. These skeletal frames come in sizes ranging from 39″ to 84″ in height with a 22″ base plate to provide stability. Their open design makes it easy to work on both the front and back of the mounted equipment.

When installing a skeletal frame, you should leave enough space between the rack and the wall to accommodate the installed equipment (most equipment is 6″ to 18″ deep). You should also leave enough space behind the rack for an individual to work (at least 12″ to 18″). You will also need to secure the rack to the floor so that it does not topple over.

These racks can also include cable management. If you have ever worked with a rack that has more than a few dozen patch cords connected to it with no cable management devices, then you understand just how messy skeletal racks can be. Figure 3 shows an Ortronics Mighty Mo II wall-mount rack that includes cable management.

Racks are not limited to just patch panels and network connectivity devices. Server computers, for example, can be installed into a rack-mountable chassis. Many accessories can be mounted into rack spaces, including utility shelves, monitor shelves, and keyboard shelves. Figure 4 shows some of the more common types of shelves available for 19″ racks. If you have a need for some sort of shelf not commercially available, most machine shops are equipped to manufacture it.

Full Equipment Cabinets

The most expensive of your rack options, full equipment cabinets, offer the security benefits of locking cabinet doors. Full cabinets can be as simple as the ones shown in Figure 5, but they can also become quite elaborate, with Plexiglas doors and self-contained cooling systems. Racks such as the one in Figure 5 provide better physical security, cooling, and protection against electromagnetic interference than standard 19″ rack frames. In some high-security environments, this type of rack is required for LAN equipment and servers.

Cable Management Accessories

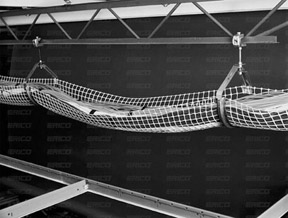

If your rack equipment does not include wire management, numerous cable management accessories, as shown in Figure 6, can suit your organizational requirements. Large telecommunications rooms can quickly make a rat's nest out of your horizontal cable runs and patch cables. Cable hangers on the front of a rack can help arrange bundles of patch cables to keep them neat and orderly. Rear-mounted cable hangers provide strain-relief anchors and can help to organize horizontal cables that terminate at the back of patch panels.

Electrical Grounding

In our discussion on conduit, we stated that regardless of your conduit solution, you will have to make sure that it complies with the ANSI/TIA-607-B Commercial Building Grounding and Bonding Requirements for Telecommunications Standard for electrical grounding. The same holds true for your cable-rack implementations. Why is this so important? Well, to put it bluntly, your network can kill you, and in this case, we're not referring to the massive coronary brought on by users' printing challenges!

For both alternating- and direct-current systems, electrons flow from a negative to a positive source, with two conductors required to complete a circuit. If a difference in resistance exists between a copper wire path and a grounding path, a voltage potential will develop between your hardware and its earth ground. In the best-case scenario, this voltage potential will form a Galvanic cell, which will simply corrode your equipment. This phenomenon is usually demonstrated in freshman chemistry classes by using a potassium-chloride salt bridge to complete the circuit between a zinc anode and a copper cathode. If the voltage potential were to become great enough, however, simply touching your wiring rack could complete the circuit and discharge enough electricity to kill you or one of your colleagues.

| Warning | Grounding is serious business and should not be undertaken by the layperson. Low voltage does not mean large shocks cannot be generated. |

We recommend working with your electrical contractor and power company to get the best and shortest ground you can afford. One way to achieve this is to deploy separate breaker boxes for each office area. Doing so will shorten the grounding length for each office or group.