We'll look at the cabling system components outlined by the TIA-569-B Commercial Building Telecommunications Pathways and Spaces Standard for concealing, protecting, and routing your cable plant. In particular, we'll describe the components used in work areas and telecommunications rooms and for horizontal and backbone cable runs. As you read these descriptions, you'll notice all components must be electrically grounded per the ANSI/TIA-607-B Commercial Building Grounding and Bonding Requirements for Telecommunications.

Conduit

Conduit is pipe. It can be metallic or nonmetallic, rigid or flexible (as permitted by the applicable electrical code), and it runs from a work area to a telecommunications room and a telecommunications room to an equipment room. One advantage of using conduit to hold your cables is that conduit may already exist in your building. Assuming the pipe has enough space, it shouldn't take long to pull your cables through it. A drawback to conduit is that it provides a finite amount of space to house cables. When drafting specifications for conduit, we recommend that you require that enough conduit be installed so that it would be only 40 percent full by your current cable needs. Conduit should be a maximum of 60 percent full. This margin leaves you with room for future growth.

According to the TIA-569-B standard, conduit can be used to route horizontal and backbone cables. Firestopped conduit can also be used to connect telecommunications rooms in multistoried buildings to an equipment room. Some local building codes require the use of conduit for all cable, both telecommunication and electrical.

In no cases should communication cables be installed in the same conduit as electrical cables without a physical barrier between them. Aside from (and because of) the obvious potential fire hazard, it is not allowed by the NEC.

Cable Trays

As an alternative to conduit, cable trays can be installed to route your cable. Cable trays are typically wire racks specially designed to support the weight of a cable infrastructure. They provide an ideal way to manage a large number of horizontal runs. Cables simply lie within the tray, so they are very accessible when it comes to maintenance and troubleshooting. The TIA-569-B standard provides for cable trays to be used for both horizontal and backbone cables.

Figure 1 shows a cable runway system. This type of runway looks like a ladder that is mounted horizontally inside the ceiling space or over the top of equipment racks in a telecommunications or equipment room. In the ceiling space, this type of runway keeps cables from being draped over the top of fluorescent lights, HVAC equipment, or ceiling tiles; the runway is also helpful in keeping cable from crossing electrical conduit. Separating the cable is especially useful near telecommunications and equipment rooms where there may be much horizontal cable coming together. When used in a telecommunications or equipment room, this runway can keep cables off the floor or can run from a rack of patch panels to an equipment rack.

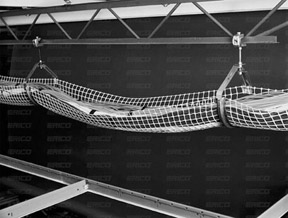

Another type of cable-suspension device is the CADDY CatTrax from ERICO. These cable trays are flexible and easy to install, and they can be installed in the ceiling space, telecommunications room, or equipment room. The CatTrax (shown in Figure 2) also keeps cables from being laid directly onto the ceiling tile of a false ceiling or across lights and electrical conduit because it provides continuous support for cables.

| Tip | Numerous alternatives to cable-tray supports are available. One of the most common is a J hook. J hooks are metal supports in the shape of an L or J that attach to beams, columns, walls, or the structural ceiling. Cables are simply draped from hook to hook. Spacing of hooks should be from 4′ to 5′ maximum, and the intervals should vary slightly to avoid the creation of harmonic intervals that may affect transmission performance. |

Raceways

Raceways are special types of conduits used for surface-mounting horizontal cables. Raceways are usually pieced together in a modular fashion with vendors providing connectors that do not exceed the minimum bend radius. Raceways are mounted on the outside of a wall in places where cable is not easily installed inside the wall; they are commonly used on walls made of brick or concrete where no telecommunications conduit has been installed. To provide for accessibility and modularity, raceways are manufactured in components (see Figure 3).

Figure 4 shows a sample of a surface-mount raceway carrying a couple of different cables; this raceway is hinged to allow cables to be easily installed.

One-piece systems usually provide a flexible joint for opening the raceway to access cables; after opening, the raceway can be snapped shut. To meet information-output needs, raceway vendors often produce modular connectors to integrate with their raceway systems.

Fiber-Protection Systems

As with raceways, fiber-protection systems (see Figure 5) are special types of conduits and cable-management systems designed specifically to address the special protection needs of optical fiber cable. Although maintaining proper bend radius is important for all cable media, severe bends in optical fiber cable will result in attenuation and eventual signal loss, which translates to lost data, troubleshooting, downed network connections, and lost productivity. Severe bends can also lead to cracking and physical failure of the fiber. By employing rounded surfaces and corners, fiber-protection systems essentially limit the degree of bending put on an optical fiber cable. To protect your fiber investment, we recommend that you consider investing in a fiber-protection system.

| KEY TERM: inner duct | Inner duct is a flexible plastic conduit system often used inside a larger conduit; fiber-optic cable is run through it for an additional layer of protection. |

When evaluating a prospective fiber-protection system, you should account for the total cost of the installation rather than just the cost of materials. Also ensure that it will support the weight of your cable without sagging. In addition, because your network will grow with time, you should consider how flexible the solution will be for future modifications. Will you be able to add new segments or vertical drops without having to move existing cable? The most expensive part of your system will be the labor costs associated with the installation. Does the system require special tools to install, or does it snap together in a modular fashion?

I am really interested in this site.This site is really good and interesting.Thank you very much for this.

ReplyDeletecable trays

great post , thank u for your blog visit us fiber optic solutions in dubai

ReplyDeletethankz

ReplyDeletePassive Networking

Nice post..

ReplyDeletePlannco Steel Products Pvt. Ltd. is a leading high-quality Cable Raceways Manufacturers , offering efficient, durable and organized cable management solutions for commercial, industrial, and residential spaces. Our customizable raceways ensure safe and clutter-free wiring, built with premium-grade materials for strength and longevity. Optimize your electrical setups with reliable, scalable and cost-effective solutions from Plannco Steel.

Keeping cables organized and secure is a key part of any electrical or industrial project, but finding reliable products can sometimes be difficult. While exploring solutions, I found this page, which provides a wide selection of cable ties, wiring accessories, and other tools designed for effective cable management. The focus on durable, factory-direct quality and bulk ordering makes it a valuable resource for anyone looking to streamline their cable setup efficiently.

ReplyDeleteExcellent read! Managing cables properly helps prevent many industrial issues. We’re a trusted bulk cable tie supplier and manufacturer offering a full range of fastening and labeling solutions. For anyone sourcing quality cable ties, visit Anhui Shangbo Plastics today.

ReplyDelete